Custom A-Frame Home: Modern Expression Meets Black Hills Beauty

Posted on: July 24, 2025

“A-Frame of Mind”: A Custom Residence in Powder House Pass

Nestled among the pines of South Dakota’s Black Hills, “A-Frame of Mind”, built by Lighthouse Construction, redefines alpine architecture. This custom A-frame home perfectly marries geometric clarity with a meticulously layered wood palette, echoing the surrounding landscape. Montana Timber Products proudly supplied a collection of custom-milled profiles and finishes that make this residence a standout example of modern mountain living.

PROJECT DETAILS

Location

Lead, South Dakota – Powder House Pass

Project Type

Custom Mountain Residence

Builder

Lighthouse Construction

Photography

Lighthouse Construction

THE DESIGN CHALLENGE

Crafting a Custom A-Frame with Natural Wood Finishes

The vision for this A-frame home was to create an exterior envelope that not only visually anchors its modern structure and offers exceptional protection, but also boasts seamless finishing integration, flowing from the exterior soffit directly into the dramatic interior ceiling. The key was to achieve a balanced modern rustic look across siding, trims, beams, and soffit, incorporating clean lines, subtle color blocking, and tactile contrast, all while ensuring a cohesive aesthetic from the outside in.

THE SOLUTION

Custom Profiles & Finishes from Montana Timber Products

Montana Timber Products delivered a suite of solutions from two distinguished product lines—ranchwood™ Artisan and AquaFir™—all crafted from sustainably sourced Douglas Fir. By combining raked, smooth, and re-sawn textures in a coordinated palette, this custom A-frame home boasts a cohesive yet multidimensional façade that celebrates both innovative design and regional character.

PRODUCTS + APPLICATIONS

| Application | Product Line | Profile | Texture | Color | Dimensions |

|---|---|---|---|---|---|

| Siding | ranchwood™ Artisan | Shiplap | Raked | ash glacier grey | 1″ x 6″ |

| Trim (Black) | AquaFir™ | Square Edge | Smooth | black | 1″ x 4″, 6″, 8″, 12″ |

| Trim (Accent) | ranchwood™ Artisan | Square Edge | Raked | ash glacier grey | 1″ x 4″ |

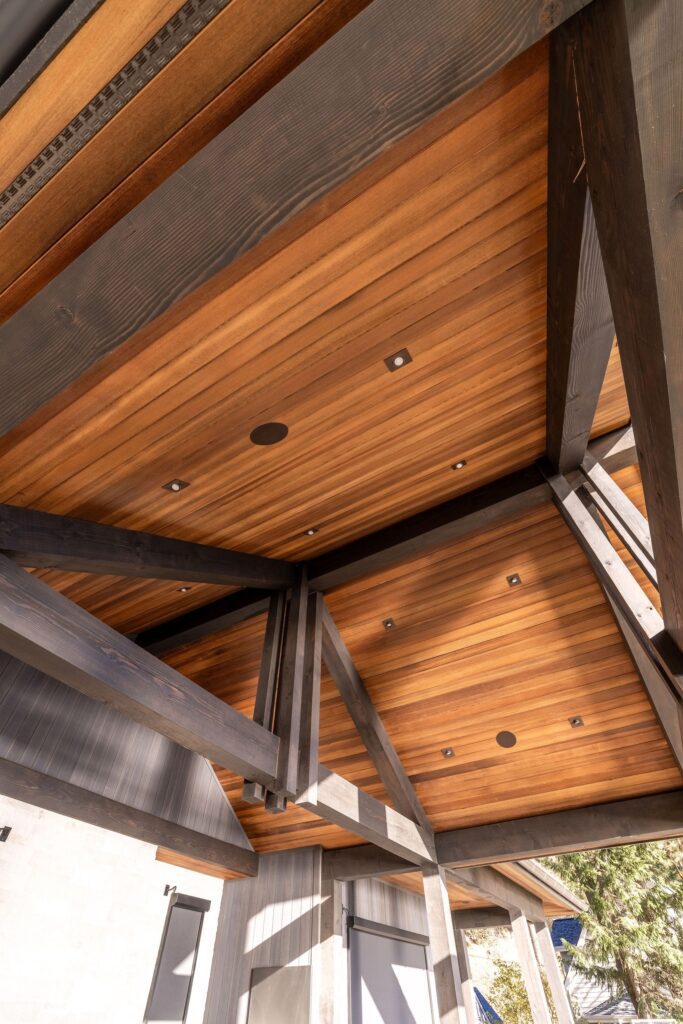

| Interior Ceiling & Soffit | AquaFir™ | Custom Bevel T&G | Smooth | yukon | 1″ x 6″ |

| Exterior Beams | AquaFir™ | Square Edge | Re-Sawn | black | 8″ x 12″ |

SPECIES + GRADE

Siding, Soffit, Ceilings and Trim: Douglas Fir | Knotty #2Btr

Timber Beams: Douglas Fir | #1 FOHC

DESIGN CONSIDERATIONS

Blending Rustic Wood Textures with Modern Detail

This custom A-frame home integrates a dynamic array of profiles and stain treatments to create dramatic shadow lines and nuanced surface character.

- Striking Exterior Contrasts: The ranchwood™ Artisan siding’s raked finish in Ash Glacier Grey offers a time-worn patina that harmonizes with the setting, while bold black AquaFir™ trim and beams provide striking, contemporary contrast. This interplay is particularly evident on the garage, where AquaFir Black trim frames the wood panel garage door, which features warm AquaFir Yukon brown panels. This creates a sophisticated contrasting trio against the light Ash Glacier Grey siding.

- ranchwood™ Artisan: Features a multi-step finishing process for deep color variation and a reclaimed wood aesthetic, perfect for adding warmth to a modern design.

- AquaFir™: Crafted for versatility, ideal for sleek, natural wood exterior detailing that complements contemporary architecture.

- Seamless Wood Integration, Inside and Out: The exterior soffit, finished in AquaFir Yukon, seamlessly extends the home’s aesthetic, visually connecting with the massive A-frame interior ceiling paneling in AquaFir Yukon. This creates a cohesive and immersive wood experience throughout the home.

- Douglas Fir: Selected for its sustainability, structural dependability, and striking grain, offering both visual appeal and exceptional price value.

- Custom-Milled Precision: Custom-milled siding, trim, and soffits ensure a precise fit and perfect color coordination, resulting in visually clean and architecturally rigorous transitions between planes and materials.

- Built to Endure: All wood is prefinished with high-performance, Seal-Once water-based sealant, providing industry-leading resilience against moisture, sun, and seasonal changes. This finish is also ideal for interior applications, ensuring a healthy living environment. This commitment to quality ensures longevity and beauty for years to come.

THE RESULT

Distinctive Custom A-frame Architecture with Enduring Materials

“A-Frame of Mind” exemplifies how the marriage of material quality and thoughtful design delivers both immediate curb appeal and long-term satisfaction. The home’s exterior fuses mountain-modern lines with warm, natural textures and robust performance—showcasing the capacity of Montana Timber Products’ customizable wood solutions to elevate any signature project.

Project Gallery