Reducing Fire Risks: Tips and Best Practices for Fire Hardening Your Home

Posted on: March 8, 2024

Wildfires are an increasing threat to homes and properties, especially in vulnerable regions. Protecting your home from this devastating force of nature is a wise investment and a crucial safety measure.

With fire hardening and home hardening techniques, you can significantly reduce the risk of your home catching fire during a wildfire.

Below, we will guide you through the process of hardening your home, creating a fire-resistant landscape, and complying with standard practices to ensure maximum protection.

Key Takeaways

- Understand and assess the wildfire risk for your home

- Implement fire prevention measures such as creating defensible space zones, using fire-resistant building materials, protecting vulnerable features & ensuring emergency vehicle access

- Comply with local building codes to ensure adequate protection from wildfires

Understanding Fire Hardening and Home Hardening

Fire hardening your home is a process designed to reduce ignition risk and make a home more resistant to radiant heat and direct flame contact from wildfires. It serves a critical role in defending homes against wildfires and adheres to the National Fire Protection Association guidelines.

The steps involved in hardening a home include:

- Assessing the wildfire risk

- Creating a fire-resistant landscape

- Selecting fire-resistant building materials

- Protecting vulnerable home features

- Ensuring accessibility for emergency vehicles

- Planning for water supply and firefighting equipment

- Complying with relevant building codes and standards

Homeowners looking to get started can use resources like the Fire Adapted Communities Learning Network, the Fire Adapted Communities Self-Assessment Tool (FAC SAT), and FAC Net. These offer guidance on correctly storing and handling combustible and flammable liquids.

Assessing Wildfire Risk for Your Home or Business

Assessing your home or business’ wildfire risk begins with examining the Immediate Zone, which extends 0-5 feet from your residence.

In this zone, flammable materials should be minimized to reduce the risk of ignition. To increase your home’s wildfire resistance in the Immediate Zone, use ignition-resistant siding, roofs, decks, attic vents, eaves, and windows, and remove flammable vegetation.

In the Intermediate Zone, careful landscaping can be employed to reduce the continuity of fuels and impede the spread of fire. For example, removing branches that overhang the structure is a critical step to help ensure your home doesn’t catch fire.

In the Extended Zone, trees and vegetation should be spaced and pruned to reduce the size of flames, keep them closer to the ground, and interrupt the fire’s path. For safety reasons, combustible materials should not be stored on or under decks in the Immediate Zone, as flying embers can easily ignite them during a wildfire.

Creating a Fire-Resistant Landscape

Reducing wildfire risk involves:

- Establishing defensible space zones around your home

- Creating fuel breaks

- Maintaining trees to minimize the chances of your home catching fire during a wildfire.

The following sections provide a detailed exploration of defensible space zones, fuel breaks, and tree maintenance.

Defensible Space Zones

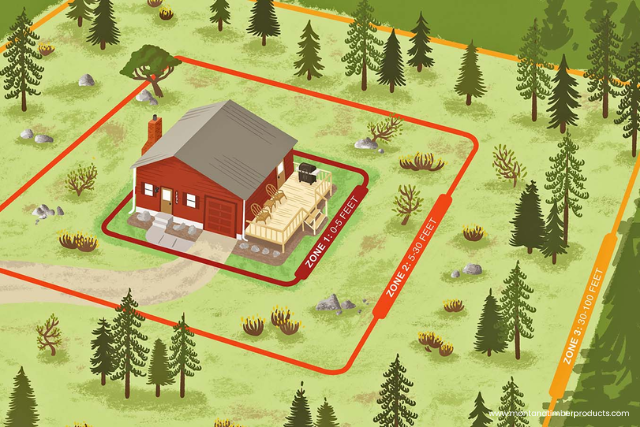

Defensible space zones are areas surrounding a dwelling and its surrounding property cleared of combustible materials and vegetation to create a separation between the home and potential fuel sources. According to the Colorado State Forest Service, there are three home ignition zones:

- Zone 1: which extends up to 5 feet from the home

- Zone 2: which extends from the outer edge of Zone 1 to 30 feet from the home

- Zone 3: aims to decrease the concentration of combustible vegetation and create an environment that restricts the advancement of fire.

The objective of interrupting the fire’s progression in Zone 2 is to contain the flames and ensure they remain on the ground. To achieve this, the following measures should be taken:

- Clear vegetation from beneath propane tanks

- Maintain a low density of fuels around the residence to provide additional time in the event of a fire

- The recommended spacing between trees and bushes in Zone 2 is at least 10 feet.

Fuel Breaks

Fuel breaks are strategically placed barriers that slow or stop the spread of wildfires. They are integral to wildfire prevention, as they regulate forest fuels and reduce fire intensity. Various fuel breaks exist, including:

- Shaded fuel breaks

- Brown strips

- Mowed fuel breaks

- Targeted grazed fuel breaks

- Mechanical treatments

- Manual treatments

- Chemical treatments

- Biological treatments

- Prescribed fire treatments

To create adequate fuel breaks, homeowners should:

- Prioritize assets and valued resources

- Treat or graze vegetative fuel breaks to manage excess litter and invasive plants

- Focus fuels reduction efforts in the Wildland-Urban Interface (WUI) zone

- Consider factors such as suppression, weather, and fire behavior

- Establish shaded fuel breaks

A fuel break for residential properties typically ranges from 2 to 15 feet in width, depending on the type of forest, fuel loading, and the recommendations of a wildland fire fuels specialist or Area Forester.

Tree Maintenance

Regular tree maintenance in wildfire-prone areas can help prevent the spread of fire. Here are some steps you can take:

- Prune and remove dead branches to reduce the risk of fire hazards.

- Maintain proper spacing between trees to help mitigate the risk.

- Remove debris and excess yard waste to prevent fire from spreading. Late winter, from mid-February through early March, is the ideal time for pruning trees for wildfire prevention. Trees are still dormant, allowing maximum growth and the chance to identify and address potential problem areas.

When it comes to pruning trees in Zone 1, the focus is on preventing the spread of fire through foliage or vegetation. Removing low-hanging branches, shrubs, and other vegetation is a way to reduce the risk of a wildfire reaching the tree canopy. This is an essential step in preemptively protecting trees from wildfires. Regular tree maintenance not only keeps your property safe but also contributes to the overall health of your trees.

Selecting Fire-Resistant Building Materials

Selecting fire-resistant building materials is pivotal in fire-resistant construction, shielding your home from wildfires. Materials such as:

- Metal

- Concrete

- Clay tiles

- Fiber cement siding

- Fire Treated Wood Siding

- Tempered glass

- Dual-pane windows

- Solid-core doors

Taking measures to interrupt a fire’s path can significantly reduce the risk of your home catching fire during a wildfire.

The following sections delve deeper into fire-resistant roofing materials, siding options, and window and door choices.

Roofing Materials

The choice of fire-resistant roofing materials is critical to diminishing the likelihood of your home catching fire during a wildfire. Some fire-resistant roofing materials include:

- Composition

- Metal

- Clay

- Tile

To ensure the protection of your home’s roof, it is advisable to regularly remove any combustible debris, such as dry leaves, moss, and trash, from the roof.

The fire-resistance ratings for different roofing materials are classified as follows:

- Class A: provides the highest level of fire resistance

- Class B: provides moderate fire resistance

- Class C: provides minimal fire resistance

- Unrated: does not have a specified fire-resistance rating

When selecting roofing materials, it is essential to consider local building codes and regulations. In addition, make sure to enclose eaves with fire-resistant materials to reduce the fire risk.

Siding Options

Choosing fire-resistant siding options can significantly shield your home’s exterior from wildfires. Fiber cement, stucco, and pre-treated wood are all fire-resistant siding options.

When selecting siding materials, connecting the siding from the foundation to the roof is essential to prevent the passage of flames and embers.

Pre-treating wood to make it fire-resistant involves applying a fire-retardant treatment to the wood surface or impregnating it into the wood.

At Montana Timber Products, we offer both options.

Material that gets our Fireline Pressure-Treated treatment goes through a certified pressure-treatment process and exceeds the most stringent fire suppression standards, such as building in areas designated by the Wildland Urban Interface (WUI) code.

For those areas where fire can still be a threat (but they aren’t considered Wildland Urban Interface zones), our FlameShield Topical is an excellent fire treatment option.

FlameShield Topical is an invisible, Class A-Rated fire retardant that reduces flame spread and smoke development. Our specialized non-toxic formula is UL Greenguard Gold Certified with low VOC content and emissions. Once properly coated, dried, and cured into the wood substrate in our facility, it is permanent and never needs to be reapplied.

If you want to learn more about our fire treatment options for natural wood products, check out our website’s Fire Treatment for Wood page.

Protecting Vulnerable Home Features

Minimizing wildfire damage requires a focus on safeguarding vulnerable home features such as vents, rain gutters, and garages. In the following sections, we will discuss the importance of protecting ventilation and attic vents, rain gutters, roof debris, garages, and storage sheds.

Ventilation and Attic Vents

Installing metal mesh screens on ventilation and attic vents is essential for preventing embers from entering your home during a wildfire. For fire resistance, 1/8-inch or 1/16-inch wire mesh is recommended for metal mesh screens on ventilation and attic vents. Fiberglass or plastic mesh should be avoided as they can melt and burn.

To ensure proper installation of metal mesh screens on ventilation and attic vents, follow these steps:

- Select a metal mesh screen with a maximum opening size of 1/8 inch.

- Securely attach the metal mesh screen to the vents, including under-eave and soffit vents and exterior attic vents.

- Consider using baffles in addition to the metal mesh screen for vents in eaves or cornices.

- Ensure the metal mesh screen is firmly attached to the vents for maximum protection.

Rain Gutters and Roof Debris

Regularly cleaning rain gutters and removing roof debris is essential for reducing the risk of fire spreading to your home. It is advisable to clean gutters bi-annually, in the spring and autumn, to reduce the risk of fire effectively.

Some practical ways to remove combustible debris from rain gutters include:

- Utilizing a wet/dry vacuum with applicable accessories

- Manually clearing the gutters and flushing them with water

- Using a leaf blower

- Washing away small particles and dirt with a garden hose or pressure washer

- Performing regular gutter cleaning and upkeep.

Garage and Storage Sheds

Hardening your garage and storage sheds protects your property from wildfires. To do so, install weather stripping around garage doors, store flammable objects at a safe distance from the door, and cover windows and vents with metal mesh. Metal sheds and steel buildings are generally regarded as the most fire-resistant materials in garages and storage sheds.

To reduce fire risk, follow these guidelines:

- Store flammable objects at least 10 feet away from the garage or shed.

- Cover windows and vents in garages and sheds with 1/16-inch or 1/8-inch wire mesh.

- Avoid using fiberglass or plastic mesh, as they may melt and burn.

Ensuring Accessibility for Emergency Vehicles

It’s vital to your property’s safety and that of firefighters to ensure your driveway and access roads are wide enough and free from obstructions, allowing emergency vehicles to reach your home during a wildfire. The recommended width for driveways to ensure accessibility for emergency vehicles during wildfires is 28 feet, with a minimum vertical clearance of 14 feet. Having a visible address number is also beneficial to firefighters in locating your residence quickly.

To ensure clear passage for emergency vehicles, the following actions should be taken:

- Regular mowing and trimming of trees and bushes

- Removal of overgrown branches and vegetation that obstruct visibility

- Trimming back tree limbs and vegetation from sidewalks

- Removal of trees or plants near fire hydrants

- Creating spacing between shrubs and trees

Planning for Water Supply and Firefighting Equipment

Proactive planning is vital to safeguard your home in the event of a wildfire. Here are some steps you can take to be prepared:

- Ensure you have an accessible water supply. This can include installing a water storage tank or connecting to a nearby water source.

- Invest in firefighting equipment. Non-collapsible fabric fire hoses or hoses designed explicitly for firefighting purposes are the most suitable options for firefighting scenarios at home.

- Consider acquiring equipment such as electric pumps, portable tanks, and wildland firefighting equipment like engines, water tenders, dozers, and caterers.

By taking these steps, you can increase your readiness and protect your home from a wildfire.

It is also essential for homeowners to have emergency kits with items like:

- water

- food

- flashlights

- batteries

- first-aid supplies

- prescription drugs

- clothing

Consult with local fire departments or fire safety experts to determine the amount of water needed to extinguish a fire in your specific building during the pre-planning stage.

Complying with Building Codes and Standards

Adherence to local building codes and standards is crucial in optimizing your home’s fire resistance. The relevant building codes and standards for fire resistance include the NFPA Codes and Standards, the International Building Code (IBC), and Fire Prevention and Safety Codes. These codes and standards are in place to ensure people’s safety and the public’s welfare by regulating design, construction practices, and the quality of construction materials.

Building codes and standards for fire resistance can vary regionally, considering factors such as climate, local building materials, and historical fire incidents.

Therefore, it is essential to refer to the specific building codes and standards of the region where the construction occurs to guarantee compliance with local fire resistance regulations.

Summary

In conclusion, fireproofing and implementing home hardening techniques are essential to protecting your property from the devastating effects of wildfires.

By assessing your home’s wildfire risk, creating a fire-resistant landscape, selecting fire-resistant building materials, protecting vulnerable home features, ensuring accessibility for emergency vehicles, planning for water supply and firefighting equipment, and complying with building codes and standards, you can significantly reduce the risk of your home catching fire during a wildfire.

Frequently Asked Questions

Can you completely fireproof a house?

It is not possible to completely fireproof a house, but by using fire-resistant or fire-retardant building materials, you can reduce the danger of fire threatening your property.

What is the difference between fireproof and fire-resistant?

Fireproofing and fire resistance are not the same, as fireproofing involves protecting the material from combusting, while fire resistance entails protecting the material from the effects of fire, such as heat and smoke. Knowing the difference is crucial for safeguarding homes or businesses from fires.

What are the key steps involved in fire hardening a home?

Critical steps for fire hardening involve assessing the wildfire risk, creating a fire-resistant landscape, selecting fire-resistant building materials, protecting vulnerable home features, ensuring accessibility for emergency vehicles, planning for water supply and firefighting equipment, and complying with relevant building codes and standards.